Webro

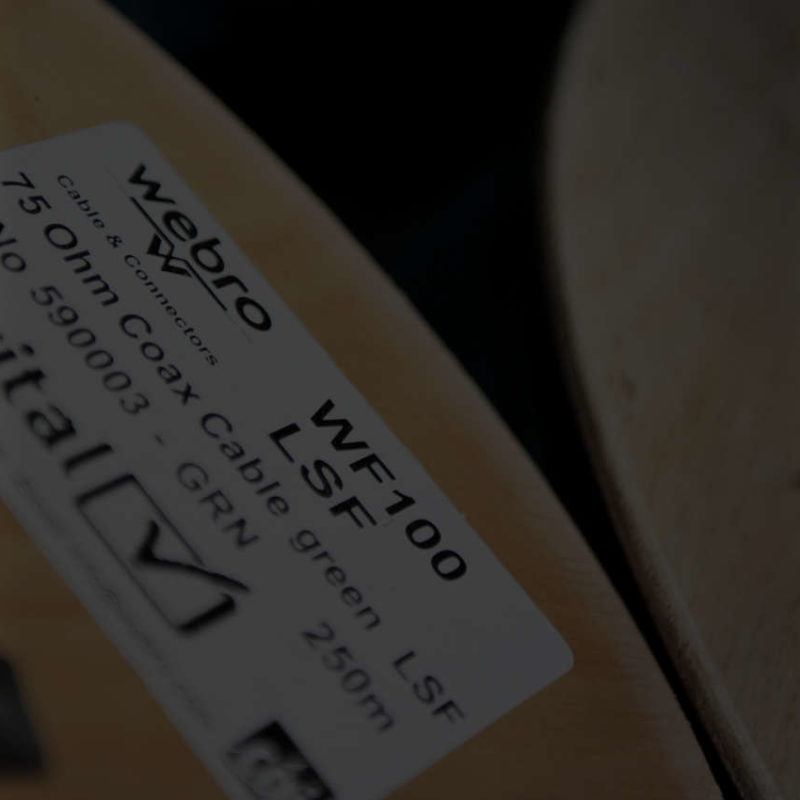

Formed in 1981, Webro is a leading supplier of high quality cables and connectors to a wide range of sectors including broadband, satellite, TV, automotive, telecoms, security and renewables.

Formed in 1981, Webro is a leading supplier of high quality cables and connectors to a wide range of sectors including broadband, satellite, TV, automotive, telecoms, security and renewables.

The £14m turnover company with a team of 24 staff supplies 1500 different lines in order sizes ranging from £150 to £20,000, to household names such as BSkyB, BBC, BT and Virgin. When it became increasingly clear that the company’s ageing paper dependent, DOS based system was getting to breaking point, Webro turned to EFACS E/8 from UK based Exel Computer Systems plc.

Peter Edginton is joint Managing Director and is the first to admit the company’s business model is far from complex. “In short we source cable from a number of different suppliers in order to supply the right cabling solutions to our customers. The only additional process that may be involved is cutting cable to specific lengths.” As he goes on to say, “Despite this, you’d be surprised at how many companies fail to be able to do this so that their customers consistently get the right product when they need it.” For Webro’s customers, this invariably means the next day and Edginton is proud of the fact that this can often be achieved, even when taking orders as late as 6pm the day before.

While the company has a consistent core customer base, there is no predictability about which customer will order what, in what amounts, and when. Given the fact its core customer base of approximately 800 companies expect next day access to over 1500 lines from 3.5mm to 25mm outer diameter, in lengths from 50m to 1000m, it’s no wonder that managing stock levels and the flow of goods in/out represent one of Webro’s key business challenges. This is compounded by the fact that while just over half of all of the 50 orders per day are standard “off the shelf” items, 40% are specified to order (where the customer describes their cabling requirements and asks Webro to supply accordingly) with a further 5% being completely bespoke. Order sizes can range from single rolls to multiple mixed loads all the way to an annual supply to be called off at regular intervals.

Further challenges come from the nature of supply as Edginton explains. “While 40% of our cable stock comes from Europe with a lead time of 4-6 weeks, the remainder comes from the Far East where lead times can be 12 weeks. As we can only buy mixed container loads which contain 100’s of kilometres of cable, we are continually having to anticipate what is essentially an unpredictable market.” As a consequence, the company’s current stockholding is almost £2.5m in order to ensure it can meet its customers’ delivery expectations.

In terms of business process flow, Webro has goods deliveries 2 to 4 times a day, every day which are unpacked, checked, stored and inventoried. Orders increasingly come in via email (70%) but 20% still involve a telephone conversation with a customer with the final 10% still coming in by fax. Once an order is confirmed and entered into the system by the sales team, a pick-list is then generated which is fulfilled by the warehouse team and the order readied for despatch.

Edginton refers back to customer contact as another key challenge to the success of the business. “If a customer calls in with a query or asking for a quote, the ideal is to have all the information there at hand to deal with the query and complete the sale to the customer’s satisfaction. Each time someone has to go and check something and call the customer back, it adds to the possibility of losing a sale.” He continues, “There are also times when we have to have delicate ‘cost versus quality’ conversations with our customers. For example, a competitor may have launched a product onto the market which looks the same as one of ours but at a lower price. In reality, often the specification is lower than our product and at times, not even suitable for the customer’s requirement. The ability to have all a customer’s previous order history and product specifications immediately to hand along with visibility of actual stock levels again increases the chance of a positive sales outcome.”

Prior to investing in EFACS E/8, these challenges were tackled by a rudimentary DOS based CRM/management system supplemented by a number of spreadsheets and reliant on a considerable amount of paper. When business was especially strong, for example during the digital switchover, Edginton candidly admits it wasn’t mission critical to get everything right all the time. However, as part of the company’s commitment to ongoing continuous improvement, the system continued to be reviewed and the impact of its shortcomings became increasingly apparent. “There was a lot of data entry duplication,” he explains. “The Purchase Manager would take information from the IT system and then manually enter it into a spreadsheet. Goods-in involved manually checking the received goods and entering them into the existing system, but you needed to keep all the accompanying paperwork to make sense of the data. When it came to sales orders and pick lists, we are talking more paperwork and carbon copies!”

Consequently there was very little visibility throughout the company. It was difficult to know what goods were coming in, when things were expected and even when they had arrived. Customer data and order data had to be physically looked up whenever required which meant sifting through lots of paperwork. All of which meant having to get back to the customer with the information required. Edginton adds, “There was also a divide between those using IT and those who weren’t, with each having incorrect assumptions about the other and this was having an impact on how the company operated as whole.” Add to this the growing gulf between how IT was used in the company compared to how everyone used it in the rest of daily life, coupled with the awareness that competitors were improving their systems and it was inevitable that a decision was made to look for a modern, integrated replacement.

This search began in 2010 and lasted 3-4 months where, as Edginton puts it, “we had our minds blown in a positive way.” He continues, “I always felt a lot of what we do could be automated but one of the things which stood out about EFACS E/8 was just how much it could speed things up. EFACS also stood out light years by having all your standard functionality such as Stock Management, CRM, etc., but also including other elements such as Document Management and Container Bookings as part of the integrated solution. We also liked the fact that the system was designed to be customisable to the way we wanted and needed it to work.”

A decision was therefore made to invest in EFACS E/8 in late 2012 and 9 months later, Webro had gone live. At the heart of the implementation lay the approach of identifying a positive in every part of the business that everyone using the new system would encounter on a daily basis and then focussing on delivering that. Whilst this was successfully achieved, Edginton remarks that it did have an unintended kickback, albeit only in the short term. “When people began to see not just what was going to be delivered, but also the potential for further improvement that wasn’t going to be ready from the outset, there was a slight dip in buy-in to the system. This was short lived because people soon saw how quickly and easily changes could be made.” Continuing his candid reflections he adds, “With hindsight, we didn’t make as effective use of the 9 months as we could have done which meant we weren’t as prepared as we would have liked to have been.”

This notwithstanding, go-live was a success; albeit with a lot of hard work, an element of firefighting and strong support from Exel personnel who were on-site for the first week to help. The benefits were felt very much from the outset in the form of centralised information that provided increased visibility and access, automation of simple tasks and the eradication of duplicated processes. For example, now when a customer rings for a price, there is no need for someone to physically have to go and find the relevant paperwork and call the customer back. “Now,” says Edginton, “it’s click, click, click, and there it is while you’re still having the conversation.” He cites another example, this time relating to real-time stock level visibility. “Historically, we might have say 11.8km of a certain cable which is supplied on 1000m drums. We’d have no means of seeing whether the 0.8km comprised 2 x 400m lengths or a single 800m length. If a customer wanted a 400m length we can now see immediately if this is available and avoid unnecessary re-cutting.”

Another area where EFACS E/8 has brought benefits experienced on a daily basis is in the standardisation of product data and the instant access to past customer records. This is particularly of relevance where customers have their own internal names for Webro products which may bear no resemblance to the actual Webro product name. Previously someone would have had to check all back orders and then visually try and confirm the correct specification. And, as Edginton adds, “That’s before you have the situation where different purchasers in the same company use different names for the same product!”

Increased visibility and efficiency have also come through automation, most notably in the removal of significant amounts of the company’s paper trail. The EFACS E/8 Document Management module has been especially useful here. For example, spec sheets historically were kept in different folders on different PCs which meant finding the correct sheet whenever an order or enquiry made this necessary. Now whenever anyone looks up a specific part, the correct spec sheet is automatically available right at the point of use. Quotation management has likewise been improved in the same way, as has delivery management. Edginton again, “Previously, if there was a problem with a delivery, someone would sort it out in a variety of different paper-based ways which other people in the company might not know about. Now this is all done via EFACS’ Case Management module so everything is immediately visible to everyone.”

The increased efficiency has enabled Webro to become more effective as a business in the way it operates. For example, EFACS E/8 allows technology to be integrated throughout the warehouse which means that stock management can now be done within the warehouse where it is most effective. Another example is how the ability to automate email order acknowledgements and statements means customers are kept up-to-date at all times, which they rightfully recognise as a higher level of service. This is especially useful for larger customers requiring monthly call-offs because they now have complete confidence in the regular visibility of their order progression, “all of which adds up to one less job they have to worry about which brings peace of mind,” explains Edginton.

At the heart of the appeal of EFACS E/8 is the recognition that it is a powerful, flexible system that offers considerable scope to be used and developed in order to generate increased benefits in the future. Webro’s future plans include the adoption of non-conformance reporting as well as making increased use of the Container Booking module for pricing, whereby containers of multiple products and prices can be quickly and easily entered onto, and managed by the system. Workflow is to be extended to other areas of the business with a view to removing spreadsheets and paper wherever possible, and QR scanners are also being explored to help manage goods-in/out. One area Edginton is particularly keen to make more use of is EFACS E/8’s powerful mobile workforce capabilities. “We have a Sales Manager and three mobile Sales/Service Engineers that are highly valuable assets to us and so we want to make sure they are being best optimised.” Other plans include integrating the despatch process with the systems used by Webro’s carriers and looking to make increased use of the planning capabilities to help with forecasting.

Edginton’s conclusion therefore should come as no surprise. “From Webro’s point of view, I see us growing and EFACS growing with us; once we’ve done the next 5 things, there’ll be 5 more to do. As a company and because of the people we had in the company, our processes were fairly solid and robust, albeit reliant on paper. EFACS has taken those solid processes and given us so much more functionality and opportunity. In every area it has given us improvements.”

Contact our team of experts to discuss your business requirements. Our team will discuss how Exel’s ERP & Field Service Management software can benefit your business processes and arrange a product demonstration.

Contact Us