Electronics ERP Software

- Integrated control from design to delivery

- Real-time production data and inventory insights

- Built-in traceability for serial and batch management

- Streamlined change control and version management

- Supports lean manufacturing and continuous improvement

Benefits of Exel's Electronic ERP Software

Highly Flexible

Adaptable to Your Business

AI Enabled

Empowering Innovation with Electronics ERP

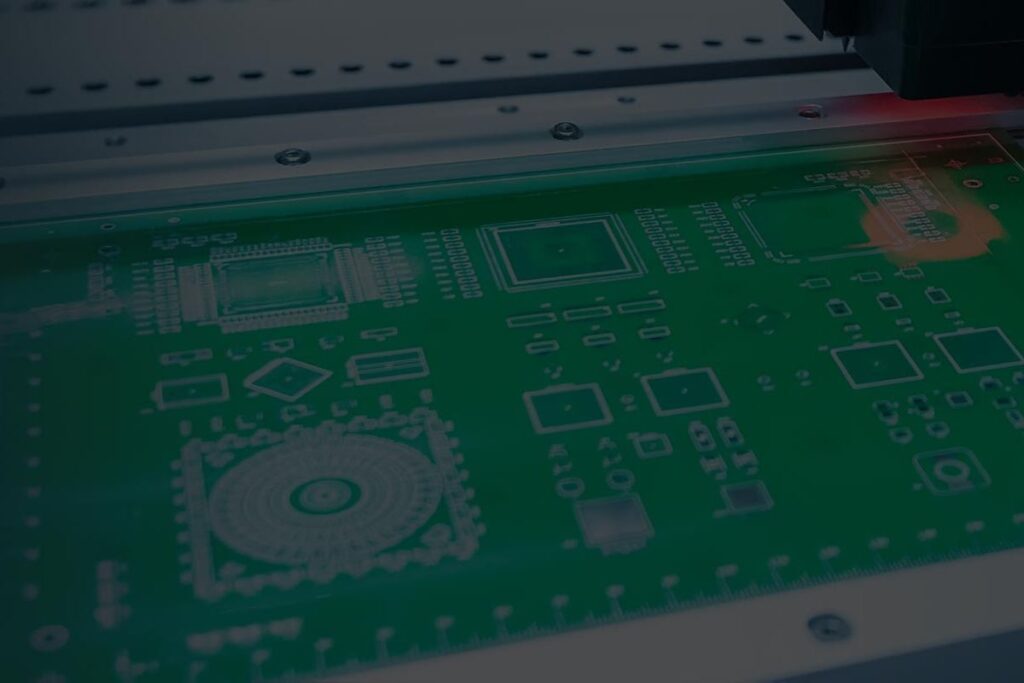

The electronics sector is fast-moving, complex, and innovation-led, with demands for tight traceability, lean production, and rapid design changes. EFACS is engineered to meet these challenges. It provides a browser-based, fully integrated ERP platform that connects every stage of your operations, from mechatronics and PCB design to supply chain and final assembly.

Whether you produce finished electronic goods, subassemblies or component parts, EFACS supports detailed engineering control, change management, and full lifecycle traceability. With integrated tools for inventory, quality, and production data capture, it empowers electronics manufacturers to operate efficiently and adapt quickly to market demands.

Enterprise Resource Planning

Smarter Manufacturing for Electronics

EFACS delivers the flexibility and control electronics manufacturers need to stay agile, reduce waste, and improve throughput, all while supporting continuous improvement methodologies like Lean and Kanban.

With advanced planning and real-time data tools, EFACS helps manage:

- Multi-stage, high-precision assemblies

- PCB and mechatronic production workflows

- Efficient inventory utilisation and stock control

- Shorter lead times through lean manufacturing practices

- Optimised production scheduling and capacity planning

The EFACS browser-based interface can be deployed on mobile devices and integrates with barcoding and RFID systems for real-time shop floor data collection (SFDC). This allows for more accurate planning, reduced delays, and better use of plant and personnel.

Download Latest Electronics ERP Brochure

Complete Control

End-to-End Traceability & Engineering Control

Traceability, compliance, and design agility are essential in the electronics sector, and EFACS supports them out of the box.

- Serial and batch traceability is built into every stage of the process

- Engineering Change Control (ECN) enables rapid yet controlled product updates

- Version-controlled document management ensures full design history

- CAD/CAM integration links engineering data to bills of material

- Inventory quarantine and quality assurance workflows support industry standards

Whether managing product variants, responding to design changes, or maintaining quality across suppliers, EFACS connects every element of your business in one auditable, optimised ERP system.

Client Case Study

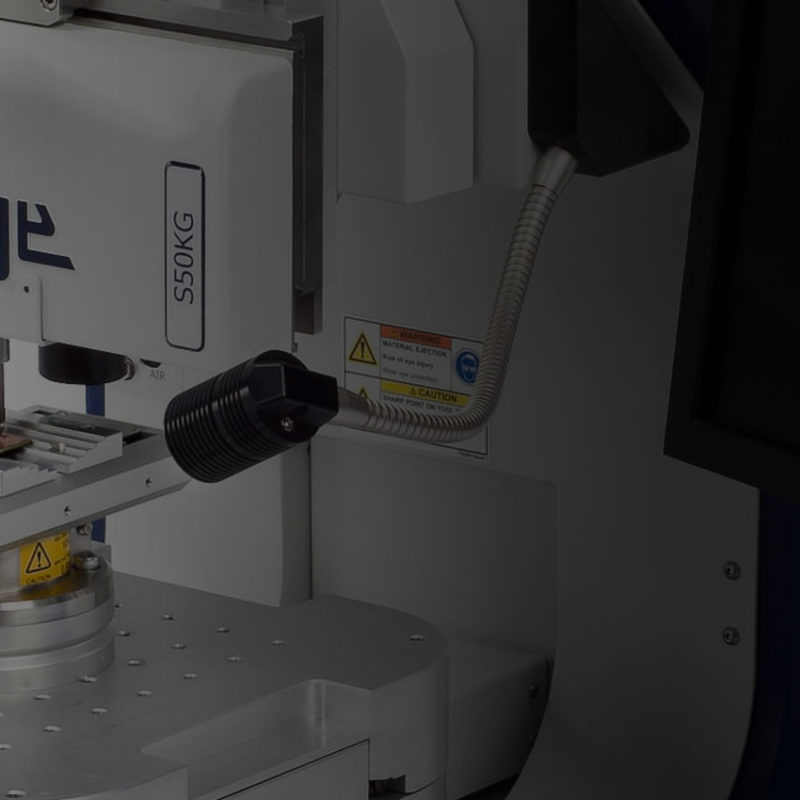

Nordson DAGE

With roots stretching back to 1961, Nordson DAGE, a divison of Nordson Corporation (NASDAQ:NDSN), is a leading supplier in the semiconductor and PCBA electronics markets, with its award winning portfolio of Bondtester and X-ray inspection systems for destructive and non-destructive mechanical testing and inspection of electronic components.

“EFACS E/8 has given us the stability and a platform to build on for the future, including the improved interconnectivity and visibility that we need for our corporate requirements.” Phil Vere, President of Nordson DAGE.

Your Benefits

Electronic ERP Benefits

Field service

EFACS E/8 delivers all the essential tools needed to manage a field service division or an entire service-led operation. Its intelligent Engineer Scheduling board streamlines job allocation, while the intuitive mobile app gives engineers the functionality they need on the go. Combined with the depth of EFACS E/8’s back-office capabilities, handling planned and reactive service work becomes significantly more efficient.

Accurate financial management

The EFACS E/8 finance suite includes:

- A comprehensive range of accounting modules

- Accurate, real-time cohesive financial management

The system is also fully aligned with Making Tax Digital (MTD).

Designed around modern accounting demands, each module offers advanced reporting, flexible analysis options and OLAP tools to help teams interpret financial data with speed and accuracy.

Workflow

The Workflow engine within EFACS E/8 automates day-to-day business processes, greatly improving operational efficiency. By ensuring tasks progress smoothly and consistently, Workflow helps maintain accuracy across orders and administrative activity.

EFACS E/8 Workflow supports:

- Receipts of orders

- Automated emails

- Reminders

- Much more

Touchscreen solutions

EFACS E/8 works seamlessly with handheld devices, tablets and mounted screens. The platform integrates with barcode scanners, enabling quick and reliable entry of product and inventory data throughout the shop floor.

Document management

Whether created internally or received from external partners, documents can be securely stored and viewed directly in EFACS E/8. Built-in Audit Trail tools make tracking and managing revisions straightforward and transparent.

Mobile solutions

Where computer access is limited, EFACS E/8 offers built-in mobile connectivity. Staff can reach the information and tools they require via their smartphones or tablets, ensuring smooth operations across the business.

Audit trail

The EFACS E/8 Audit Trail module records and tracks all activity within the system, allowing teams to review, trace and investigate data changes whenever required.

Multi-language

EFACS E/8 includes extensive functionality for organisations that operate in more than one language, supporting global teams and multilingual environments.

Customisation toolkit

EFACS E/8 has the flexibility to be shaped around unique business needs. The customisation toolkit empowers teams to adapt screens, extend functionality and create tailored applications designed for specific roles and processes.

Business process automation

EFACS E/8 streamlines routine tasks, including:

- Sending confirmation of orders

- Linking up processes

- Automating processes

As each step completes, the system can automatically trigger the next stage, freeing staff to focus on high-value work.

Business intelligence

EFACS E/8 delivers accessible reporting, presenting vital insights to the right people at the right time. Role-based permissions ensure employees only see the data relevant to their responsibilities.

Holistic and connected

With decades of continuous development behind it, EFACS E/8 provides a complete platform for managing modern manufacturing operations. Recent AI-powered enhancements further strengthen its ability to support businesses as they evolve.

Our experts are on hand to discuss your project

Contact our team of experts to discuss your business requirements. Our team will discuss how Exel’s ERP software can benefit your business processes and arrange a product demonstration.

Contact Us