Engineering ERP Software

- Integrated control from design to delivery

- Real-time production data and inventory insights

- Built-in traceability for serial and batch management

- Streamlined change control and version management

- Supports lean manufacturing and continuous improvement

Benefits of Exel's Engineering ERP Software

Highly Flexible

Adaptable to Your Business

AI Enabled

Engineering ERP for Modern Manufacturing Environments

The engineering sector demands operational flexibility, process control, and full visibility across complex workflows. EFACS is built to meet these challenges, offering a browser-based, fully integrated ERP platform that unifies functions from production planning and scheduling to inventory control, traceability, and quality assurance.

Whether you manufacture one-off prototypes, tooling, or high-volume parts, EFACS adapts to the way you work. With embedded support for a wide range of engineering processes, including machining, fabrication, welding, forming, and finishing, it enables engineering businesses to reduce waste, meet delivery deadlines, and maintain rigorous quality standards.

Enterprise Resource Planning

Production Agility Across Every Engineering Process

Engineering businesses need systems that support precision, responsiveness, and custom workflows. EFACS provides the tools to manage a wide variety of production environments, from bespoke assemblies to multi-operation batch jobs.

EFACS enables you to:

- Capture real-time data with barcoding and RFID

- Streamline goods receipt, assembly, and dispatch

- Optimise production capacity and resource allocation

- Deploy browser-based SFDC on client mobile devices

- Smooth demand with advanced forecasting and planning

A powerful planning engine factors in machine availability, staff skill levels, setup/clean-down time, and department capacity, all to help you balance resources and meet customer deadlines with confidence.

Check out the Engineering ERP Brochure

Control

End-to-End Traceability & Product Lifecycle Control

In engineering environments, product quality and traceability are paramount. EFACS offers built-in tools to maintain strict lifecycle control while supporting agility in design and production.

Key capabilities include:

- Engineering Change Control (ECN) for lifecycle management

- Serial number and batch traceability integrated throughout the system

- Version-controlled document management for full design accountability

- CAD/CAM integration directly linked to bills of material

- Inventory quarantine and QA procedures aligned with industry standards

Whether you’re working in machining, presswork, profiling, or multi-stage assemblies, EFACS ensures your systems are fully connected, auditable, and ready to scale with your operation.

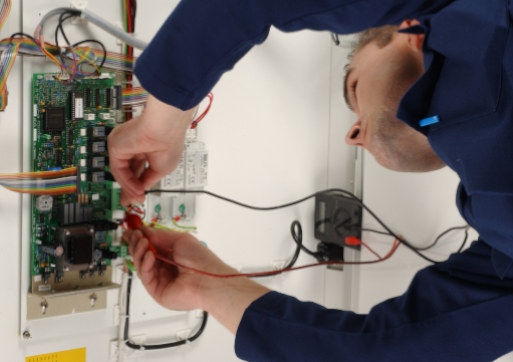

Client Case Study

HV Wooding

Founded in 1968 in a small shop in Lyminge, HV Wooding has grown to become one of the UK’s leading manufacturers of precision engineered components and assemblies. A commitment to product quality, customer service and innovation is the reason why companies such as Rolls Royce, Honeywell, Schneider Electric and ABB have worked with HV Wooding for over 30 years. Parts manufactured by HV Wooding can also be found in over 22 million UK homes and continued success has seen HV Wooding’s turnover double in six years, reaching £13.5m in 2012.

HV Wooding has five key areas of work: Busbars, Presswork, Wire Erosion, CNC Machining and Sub-assembly. With an average split between 70% Make to Order (MTO) and 30% Make to Stock (MTS), the company produces approximately 1.2 million parts per month. Depending on the nature of production, order sizes can range from single items to substantial batches measured in hundreds of thousands, with lead times varying from next day on MTS items through to months for complex custom parts where tooling also has to be designed and manufactured. In fact, all parts are manufactured to customer requirements with orders/enquiries being in the form of engineering drawings.

Your Benefits

Engineering ERP Benefits

Field service

EFACS E/8 delivers all the tools needed to operate a field service division or a dedicated service organisation. Its intelligent Assisted Engineer Scheduling board streamlines engineer allocation, while the intuitive mobile app supports engineers on the move. Combined with EFACS E/8’s comprehensive back-office capabilities, managing reactive callouts and planned maintenance becomes far more straightforward.

Accurate financial management

The EFACS E/8 finance suite includes:

- A comprehensive range of accounting modules

- Accurate, real-time cohesive financial management

EFACS E/8 also supports full compliance with Making Tax Digital (MTD).

Each financial module is designed for usability, flexibility and depth. The system uses a modern ledger architecture, supported by advanced reporting, extensive data interrogation tools and robust OLAP analysis.

Workflow

The Workflow module within EFACS E/8 streamlines everyday business processes, significantly improving administrative efficiency. Workflow helps ensure that customer orders progress without delays and that routine tasks are completed quickly and accurately.

EFACS E/8 Workflow can support:

- Receipts of orders

- Automated emails

- Reminders

- Much more

Touchscreen solutions

EFACS E/8 integrates seamlessly with handheld devices, tablets and wall-mounted screens. It also works with compatible barcode scanning equipment, making stock and product movements fast, accurate and straightforward.

Document management

All inbound and outbound documents can be securely stored and accessed inside EFACS E/8. The integrated Audit Trail controls revisions and maintains a clear, traceable history of document changes.

Mobile solutions

For employees who work away from the office or do not use desktop machines, EFACS E/8 offers mobile-friendly access as standard. Staff can reach essential tools and information directly from smartphones or tablets.

Audit trail

The Audit Trail module records and monitors every transaction within the system, providing complete transparency. It allows teams to trace changes, verify actions and review data flow throughout the organisation.

Multi-language

EFACS E/8 includes fully developed features for deploying the ERP system across multiple languages, supporting international operations with ease.

Customisation toolkit

EFACS E/8 offers extensive flexibility, enabling businesses to tailor the system’s functionality to meet specific operational needs. Using the toolkit, teams can build custom applications that support their unique workflows.

Business process automation

EFACS E/8 helps reduce time spent on repetitive administrative tasks, such as:

- Sending confirmation of orders

- Linking up processes

- Automating processes

When one activity is completed, the system initiates the next step automatically, freeing staff to focus on higher-value work.

Business intelligence

EFACS E/8 supplies visual, easy-to-understand reporting that delivers key insights to the right users. Permission-based access ensures each employee sees only the information appropriate for their role.

Holistic and connected

With continuous development since 1985, EFACS E/8 is built to support the full range of functions within a modern manufacturing environment. The addition of recent AI-driven enhancements places EFACS E/8 in a strong position to help customers evolve and future-proof their operations.

Our experts are on hand to discuss your project

Contact our team of experts to discuss your business requirements. Our team will discuss how Exel’s ERP software can benefit your business processes and arrange a product demonstration.

Contact UsEngineering ERP Frequently Asked Questions

Does it cater for Project Management & Job Costing?

The Job Costing system provides extensive reporting based on works order labour bookings compared with planned costs, actual material issues compared with planned material and actual subcontract costs incurred through the Purchase Order Processing module compared with planned subcontract costs. Analysis is available by works order, work centre, operator and section. The Project Management module provides a ‘project umbrella’ for the tendering process and subsequent management of successful contracts associated with a project.

Does it provide a Gantt chart?

It does. You can visualise the schedule effortlessly with intuitive Gantt charts, delve into resource utilisation and availability with the utilisation view, or extract relevant information through data query views. These versatile views enable analysis and interpretation of scheduling data from multiple angles.

Does it have Engineering Change Control functionality?

Yes, the Engineering Change Control facilities provide an Engineering Change Note (ECN) system and full ‘part revision’ control. A single Change Note may affect any number of parts. A flexible status system controls the state of the ECN. Parts may be managed at multiple revisions, each revision demanding a potentially different Bill of Materials and Routing definition.

Does it have Non-conformance reports (NCRs) and corrective actions?

Exel’s Engineering ERP provides a full quality management system with NCRs and corrective actions, utilising workflows to provide efficiency gains

Does it have centralised storage for project documents, CAD files and specs?

The platform has a comprehensive document management system that allows a document to be saved once and referenced in many places – it is compatible with a multitude of file types, such as Word, Excel, PDF, video, sound, images (JPG, MPG, GIF, etc.) and CAD formats such as DXF, DWG – in fact all normal formats supported within a browser environment.