The top three questions manufacturers ask themselves on a daily basis: What do we need to buy? How much do we need to buy? When do we need it by?

The top three questions manufacturers ask themselves on a daily basis: What do we need to buy? How much do we need to buy? When do we need it by?

Now, you could hold large quantities of everything you might ever need, although that makes very little commercial sense. Which is why the trend long ago moved to operating ‘Lean’; buying or making only what you need, when you need it.

Whilst most top-level ERP systems incorporate the functionality to enable lean operating, Exel’s own EFACS E/8 ERP system included, it has been Exel’s experience that very few manufacturing companies use it to its fullest, some even at all.

The reason being is that it can be incredibly time consuming. This is because so many aspects of the business are involved, which is reflected in the functional areas of the software that are required, such as Purchasing, Production, Stock Management, Suppliers….in fact, over a dozen functional areas.

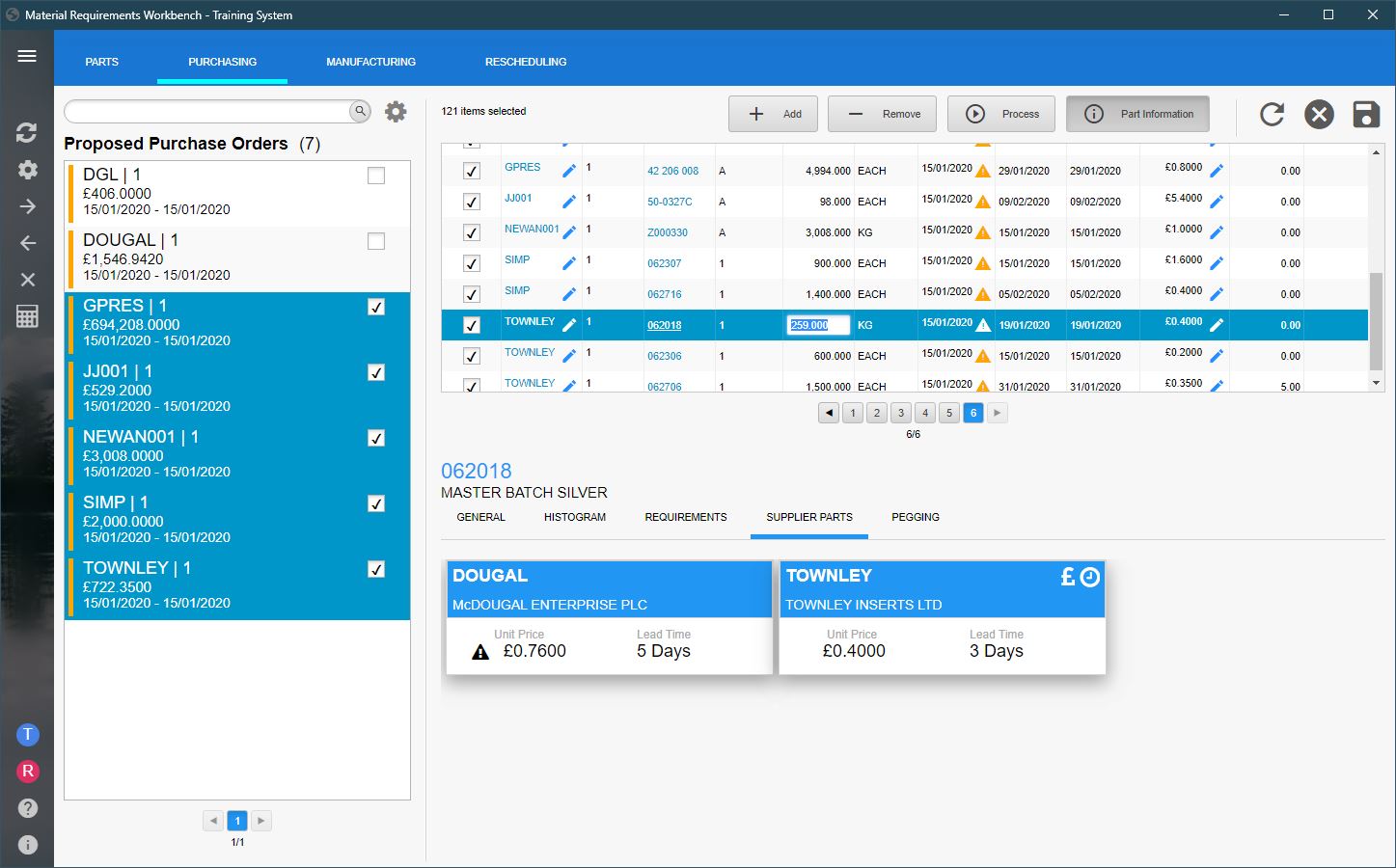

It is due to this realisation that Exel developed the EFACS MRP Workbench. This new capability is a catch-all for the aforementioned functionality; a single, centralised workspace where you can view and interact with all the required MRP data.

You can now complete actions in a single screen, call off orders for purchased parts and schedule jobs for the shop floor.

You can easily over-ride an MRP schedule and can change a previously selected item from a purchased part to a manufactured part, and vice versa, allowing you to mix and match the supply chain at ease.

The manufacturing industry is well aware that through agility you can win new clients and keep your existing clients happy. To a large degree this agility has been achieved through advanced ERP systems that are fully integrated and provide real-time data, such as EFACS E/8.

The new EFACS MRP Workbench module improves on this even further, reducing time and complexity by allowing the operator access to all the tools and information needed in a single module.

To find out more about MRP Workbench and all the benefits it can bring to your organisation, click here.